TH Series

Harmonic Roatry Table – THE CHEAP SOLUTION

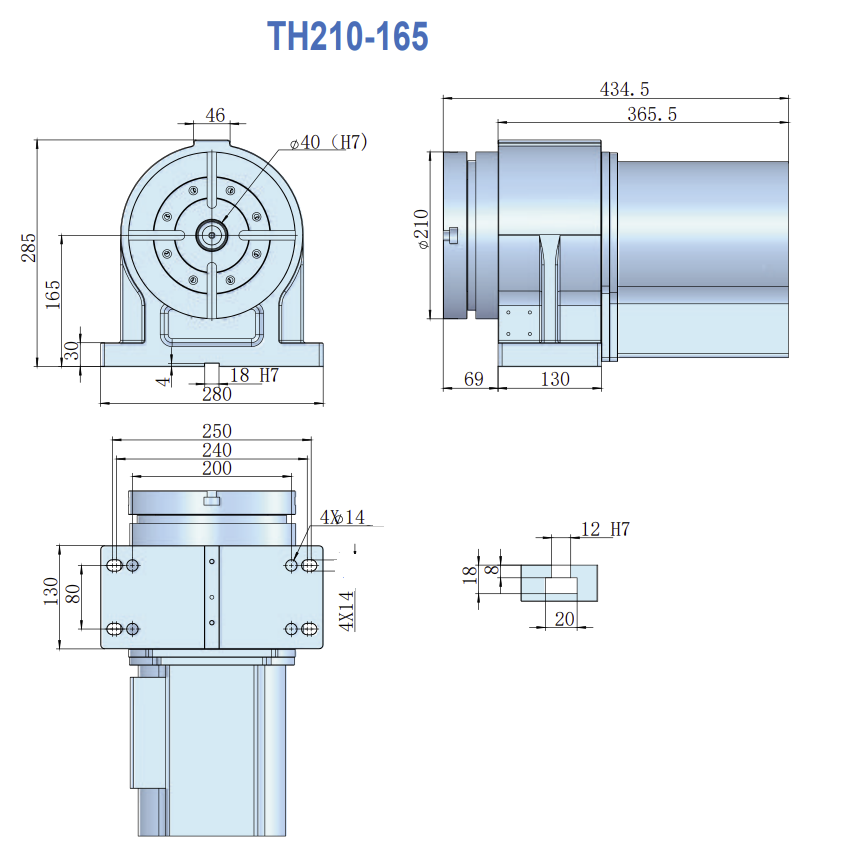

TH210-165

TH series is a CNC rotary table driven by Harmonic Drive gear, which is popularly used as a convenient positioning unit or as a fourth axis in CNC machine tools. For example, it can be installed parallel to the X-axis, Y-axis or Z-axis of the machine tool to add a rotary axis to the machine. Siemens and Bosch-Rexroth are available as drives. The TH series can be used as a dividing head or for continuous movements, enabling the machining of complex curved surfaces and extending the machining range.