V Series

4-AXIS MACHINING CENTERS

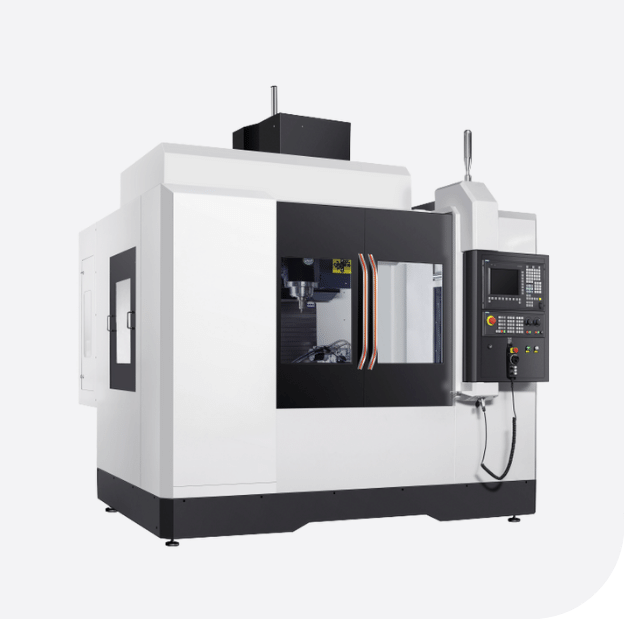

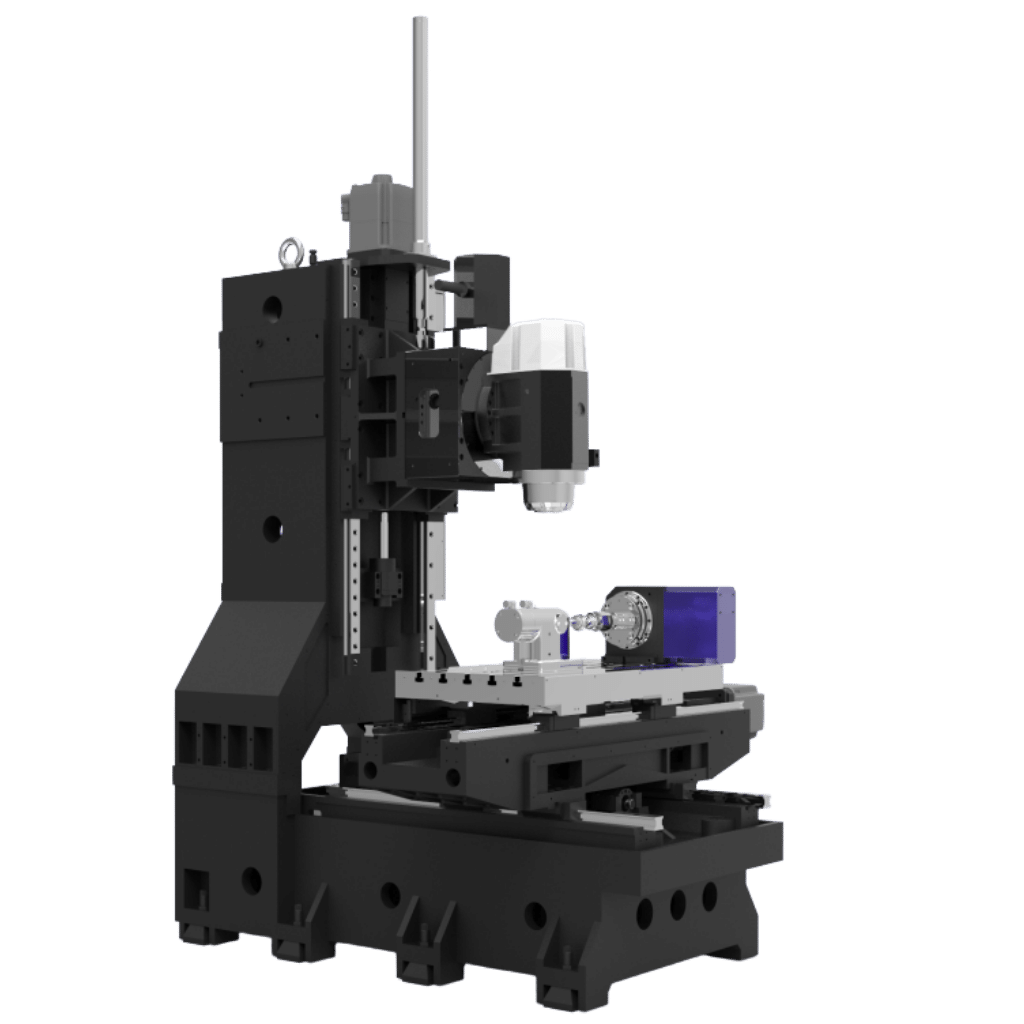

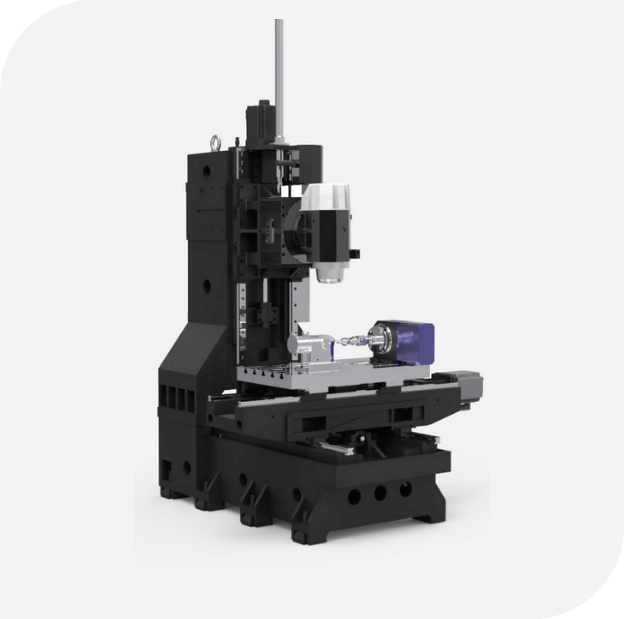

V866U 4-axis machining center

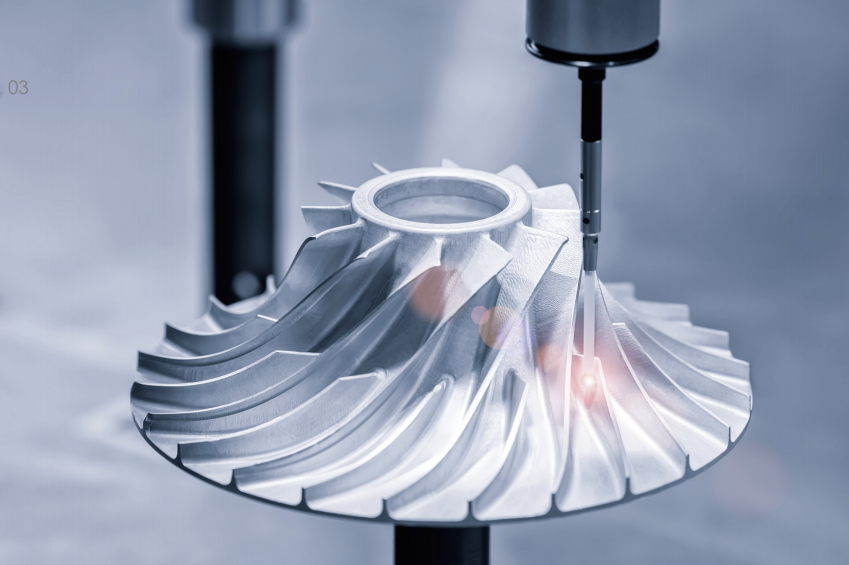

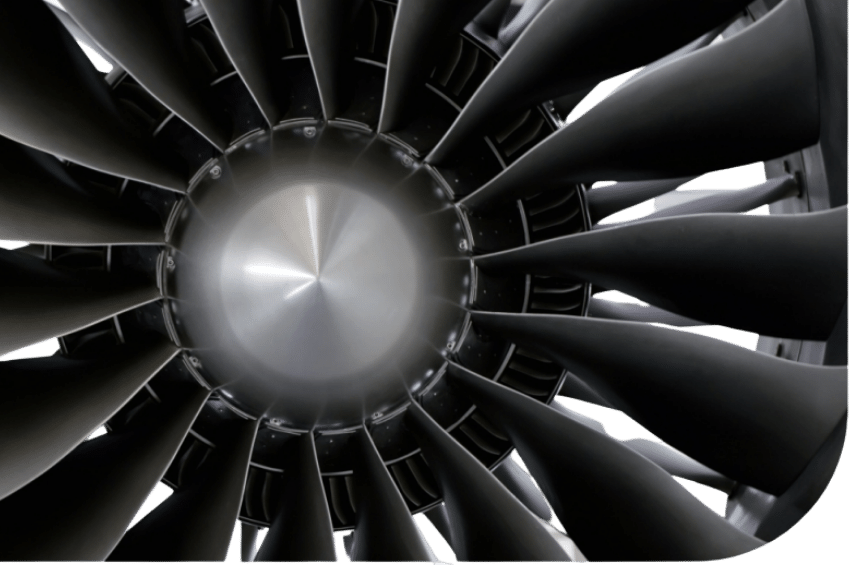

The V866U 4-axis machining center is the ideal choice for companies engaged in a wide range of productive machining and complex parts. Designed for machining long-axis parts with complex curved surfaces, such as high-precision mechanical camshafts, molds, and aerospace blades, it can automatically and continuously machine workpieces with optional auxiliary axes in a single setup. The V866U turns every manufactured component into an impressive masterpiece.