RH-Series

C-axis Rotary Table - THE FAVORITE EXPANSION

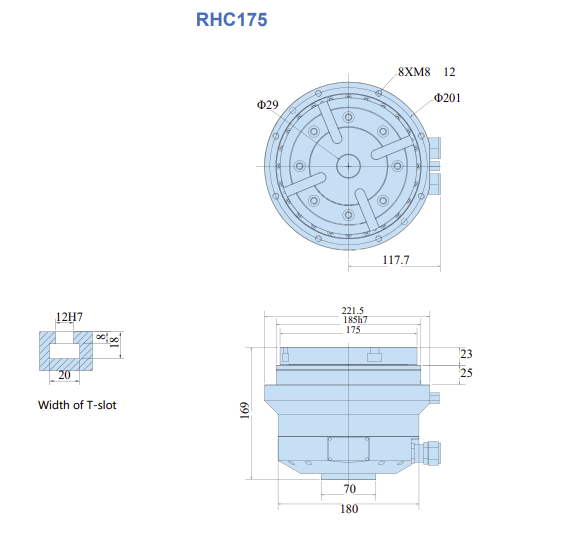

RHC175

The RH series is an optional C-axis driven by a Harmonic Drive gear and is popularly used as a low-cost positioning unit as an installation or in CNC machine tools as a fourth axis. For example, it can be installed parallel to the X-axis, Y-axis or Z-axis of the machine tool to add a rotary axis to the machine. Siemens and Bosch-Rexroth are available as drives. The RH series can be used as a dividing head or for continuous movements, which also makes it popular for use in automation and expands the machining range.