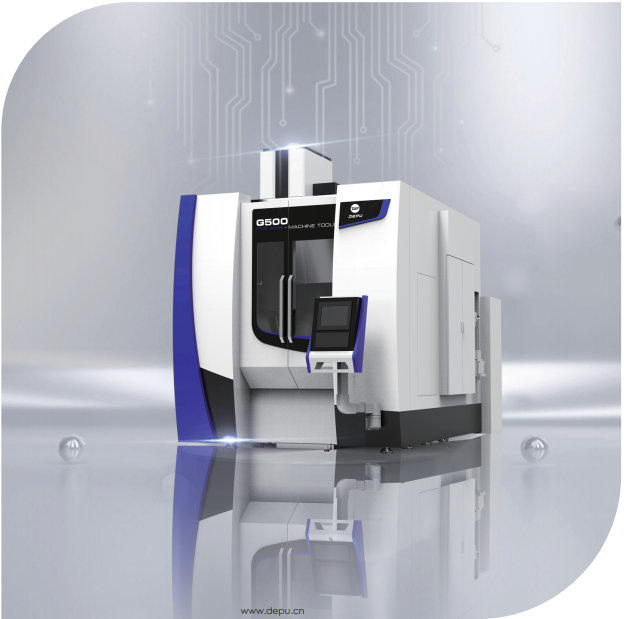

G Series 5-axis machining center

Siemens, Heidenhain, Fanuc and Bosch-Rexroth are available as controls and drives Siemens, Heidenhain and Bosch-Rexroth available

G-series machining center is a state-of-the-art 5-axis machining center based on the structure of portal milling machine. With excellent mechanical characteristics, it is equipped with high-rigidity and high-precision linear guideways and ball screws, and a double-supported rotary swivel table. This provides the machine with excellent product processing capabilities in terms of quality. An automatic pallet changing system is available as an option for uninterrupted production. The G-Series is the ideal choice for companies that demand economical precision.

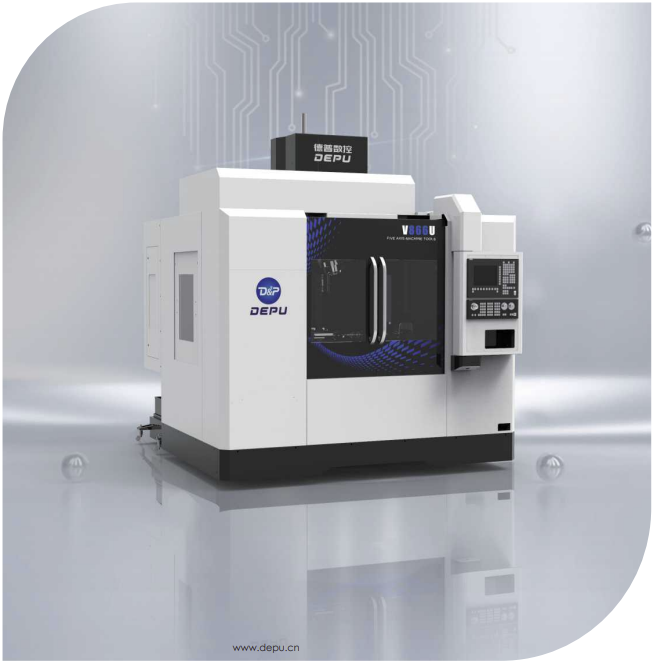

Milling machines V-Series

V series 4-axis machining center

Siemens, Heidenhain, Fanuc and Bosch-Rexroth are available as controls and drives Siemens, Heidenhain and Bosch-Rexroth available

The V-Series is a small to medium size 4-axis machine tool. The V-Series is suitable for medium and small series machining of versatile, complex parts. The machine tool adopts a stable C-type vertical structure, forming a high-precision and high-rigidity 4-axis machining center. A reasonable combination of a swivel head B-axis and optional A-axis or C-axis makes a customized machine possible. The B-axis swivel head is a self-developed, high-precision and high-rigidity roller cam mechanism, which enables continuous cutting torque up to 1560N.m.. The standard high torque and high speed motor spindle has a maximum speed of 18,000rpm and a maximum torque of 85N.m.